SUMNER, Wash. — When you order something on Amazon, you're probably thinking about what's inside -- not the package itself. But behind the scenes, Amazon is on a mission to transform every box, bag and envelope with the goal of cutting waste and protecting the planet.

Inside Amazon's Innovation Lab in Sumner, the company is rethinking everything about its packaging to make it smaller, lighter, and more sustainable -- all while ensuring your orders arrive safely.

Kayla Fenton, part of Amazon's Sustainability team, says that despite shipping billions of packages each year, the company tailors its packaging to the unique needs of each product. That could mean smaller, lighter boxes, less filler, or even eliminating packaging altogether.

"What we know is customers want to receive their item in great condition, they want to have the least amount of packaging possible that they have to manage and they also want to easily recycle it," said Fenton.

Amazon has partnered with manufacturers to create innovative solutions. For instance, a bottle of Windex used to ship in a large box stuffed with plastic pillows. Now, it ships in a custom-designed cardboard container that fits snugly around the bottle -- no filler needed. And for items like a Playmobil toy set, the item is in a reversible box which can double as festive gift wrap.

"So if you wanted to put it under the Christmas tree, a customer could," explained Fenton.

These changes support Amazon's Climate Pledge -- a commitment to reach net-zero carbon emissions by 2040. In the past five years, the company says it has eliminated over 4 million metric tons of packaging material.

One of the biggest shifts has been moving away from plastic. Just last year, about 65% of Amazon products contained plastic packaging. Today, that number is down to 37%. Amazon estimates it has avoided producing more than 15 billion plastic air pillows thanks to the switch to paper-based fillers.

"We're also really obsessed with the package size," said Fenton. "How do we get it to be the smallest size possible and the lightest amount of material?"

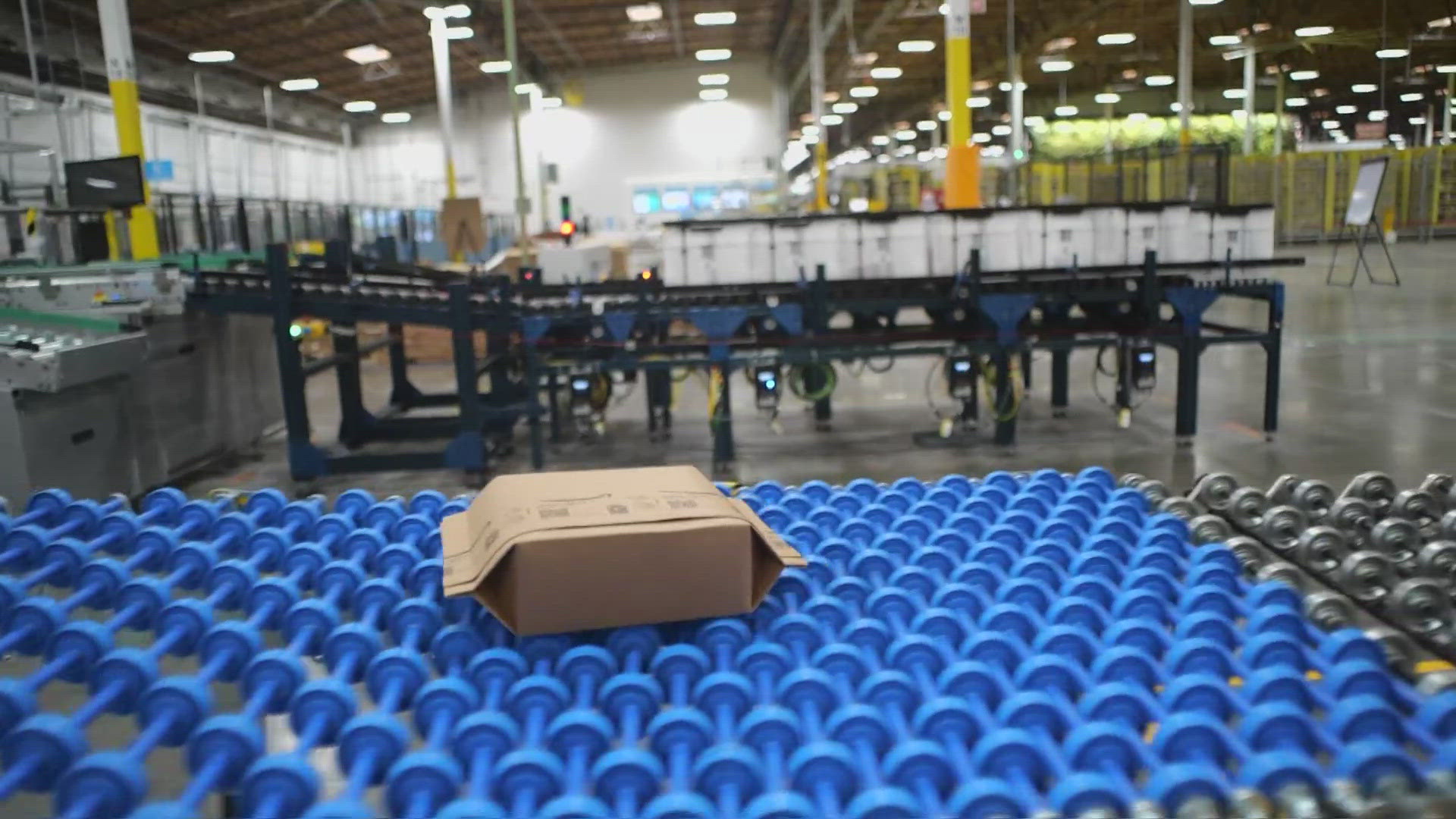

One high-tech solution: machines that scan each product and build a right-sized box on demand -- reducing the need for extra filler and cutting waste.

"It scans the item, detects the dimension of the item, and builds a package around it," said Fenton.

Of course, sustainable packaging only works if it can survive the journey from the warehouse to your front door. That's why Amazon has an entire lab dedicated to putting every new box, bag, and envelope through extreme testing.

Packages are slammed, shaken, and dropped to mimic what might happen inside a delivery truck.

"It basically mimics how a product might slide in a truck that's going at higher speeds and how that product might bump into different parts of that semi-truck," explained Fenton. "We are trying to break things so we can understand where its failure point is."

It's all part of a bigger goal: transforming how millions of packages move around the world while shrinking Amazon's environmental footprint.

Because sometimes, thinking inside the box really can make a big difference outside of it.